Lean Deployment

Executing your Lean Strategy using the 4DX Model

Align your business around metrics that matter

Unknown

It has been recognised that using a Lean Tools based approach to Lean deployment is yielding limited results. So what can Leaders do differently to achieve breakthrough results?

4 Dimensions of Excellence

Once you have your strategic and annual goals in place, the 4DX model describes how to execute this strategy with the following 4 steps:

- Identify your wildly important goals.

- Identify the leading metrics.

- Create a compelling scorecard.

- Create a cadence of accountability.

The benefits to you with this 4-step approach include:

- Focus on execution of actions that deliver specific goals.

- Drives accountability to deliver actions committed.

- Align the organisation around the metrics that matter.

The following Lean tools support the deployment of the 4DX Model.

Daily Accountability Process

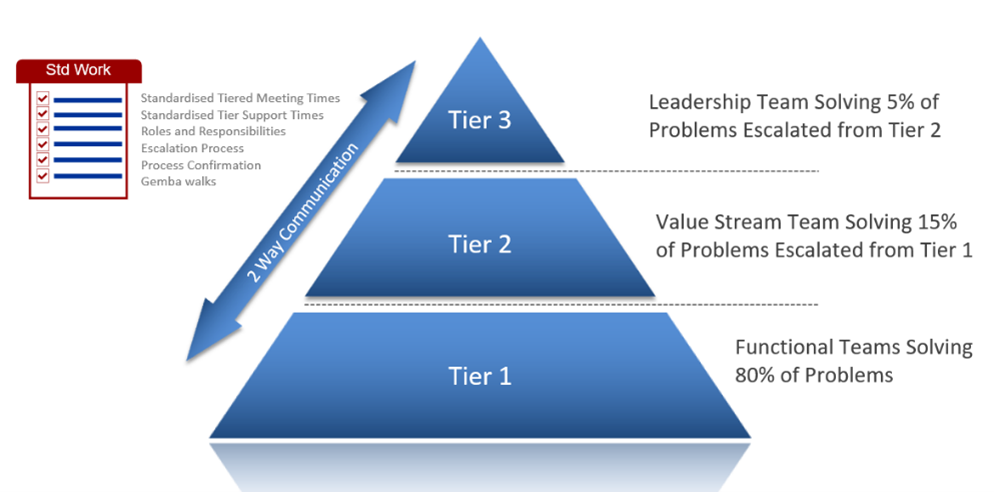

For the management of the business on a daily basis, the daily accountability is typically 3 Tiers, where each function meets at Tier 1, then escalate any exceptions to Tier 2 which is at a value stream level and the final level of escalation is to Tier 3. The purpose of this process is that Tier 1 is empowered to solve 80% of problems, Tier 2 solves 15% and Tier 3 solve the remaining 5%.

To support your deployment through change management process and workshop facilitation, CLS can enable your team to live and breathe the daily accountability process to deliver operational goals.

Problem Solving:

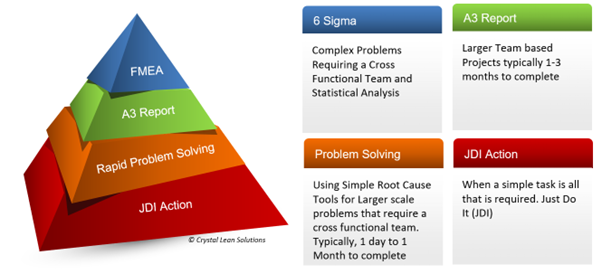

With any process, there will inevitably problems that occur that we hadn’t expected. There are a number of levels of problem solving including:

- Just Do It (JDI)

- Rapid Problem Solving

- A3 Problem Solving

- 6 Sigma

- Visit our Human Error Problem Solving page here

- Find out more about our Human Error problem solving course here

Kata Coaching:

To support a continuous improvement culture, leaders can provide coaching in the form of Kata coaching. To find out more about the 5 steps approach, visit HERE

Leader Standard Work:

To sustain Lean processes, including daily accountability process, Tiered management and problem solving, standard work is required. Standard work outlines the key activities that are critical to the management of the business, regardless of the ongoing day to day firefighting.

Gemba Walks:

Leadership has an opportunity to complete Gemba walks which is where leaders go to where the work is being performance. The role of the Gemba walk can depend on the topic which can be a Lean walk, a Recognition walk, a problem-solving walk or a Tiered board walk. The Gemba walk schedule can be part of the Tier 3 daily accountability process to continuously support Lean deployment.

6S and Visual Management:

A foundation to lean is 6S which improves the housekeeping standards of a given workplace. The key steps include:

Sort: Remove unwanted items from work environment

Simplify: Find a home for all items required

Shine: Clean as you go

Standardise: Create a housekeeping standard

Sustain: Develop a process to sustain 6S

Total Productive Maintenance:

To support the life of equipment, total productive maintenance is a 9-step programme that engages all personnel managing equipment are involved in the life of equipment. The benefits of TPM reduces unplanned downtime, improve quality, and provide predictability in asset care.

Lean Assessment:

As part of Lean deployment, when starting a programme, it is possible to use a Lean Assessment. CLS provide you with a number of assessment options including:

- MÓR Benchmarking Model

- PROBE Lean Assessment

The output provides direction to plan and execution Lean and deliver your business objectives with your team. To support your Lean assessment, CLS provide facilitation of the Lean assessment and provide coaching in the development and deployment of a Lean / Continuous Improvement plan.

Belt Programmes:

To transform the capability of your teams, it is possible to either complete modular training for Lean tools or there are Belt programmes which include:

White Belt: A half day introduction to Lean.

Yellow Belt: A 2-day training course that provides the learner with the knowledge and skills to deliver a small improvement project.

Green Belt: A 5-day training course that provides the learner with the knowledge and skills to deliver a medium to large improvement project and can mentor Yellow Belt projects.

CLS offer programmes that are customised to suit your sector including:

- Manufacturing

- Construction

- Services

Let’s Talk: Contact Us Today +353 (0)87 6226899